Algae Cultivation Bottleneck

Without enough algae, animals starve or are underfed. Hatchery operators often weigh this lost revenue against the cost of additional floorspace and staff.

Traditional low-density algae production uses significant floorspace and labor, requiring staff to regularly clean and inoculate multiple vessels.

Hidden Cost of Contaminated Algae

The true cost of poor quality algae cultures is hard to calculate, but it has major impacts on the bottom line:

- Contamination can crash algae cultures, making production unreliable and causing animals to starve or be underfed

- Pathogens in algae cultures increase mortality or kill entire cohorts

- Animals that survive early infections often have lower growth rates, resulting in lower FCR & yield, and ultimately lower margins for hatcheries and grow-outs

Algae Production Made Easy

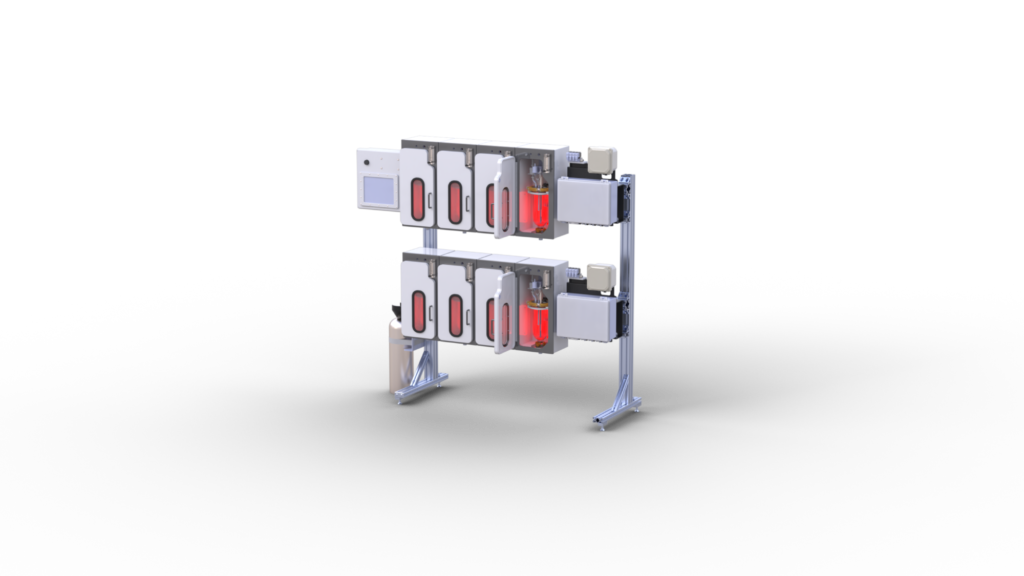

Our compact photobioreactors make it easy to continuously culture clean algae on-site.

Routine tasks like cleaning and harvesting are automated, which makes life easier for hatchery staff, while increasing reliability and reducing operating expenses.

Compact Algae Culture

Industrial Plankton’s PBRs produce more algae per square foot than any traditional method.

When building a new facility or operating in a limited space, square footage is at a premium, and low-density algae cultures waste a lot of space.

Compared to traditional culture, a PBR 1250L produces as much as a 12,000 L (30 x 400 L) continuous bag system or a 75,000L batch system, but requires only a fraction of the floor space, labor, and water.

Continuous Biosecure Algae Culture

IP’s closed PBRs use a CIP (clean-in-place) system to increase cleaning reliability and remove the tedious work of scrubbing tanks.

The sealed tank and CIP system create a pristine culture environment for continuous high-density algae growth.

Micron air and media filters extend culture life, resulting in lower labour, and reduced inoculum demand. This also increases reliability and quality of algae cultures, resulting in healthier larvae and juveniles.

Financial Impacts

- Avoid crashes, a single crash can easily cost a hatchery $20,000 in lost revenue

- Feed enough high quality algae to promote faster growth, earlier sets, and overall more production, generating more revenue per season

- Save up to $36,000 in building costs per PBR 1250L compared to building for low density standing bag culture cultures

- Reduce operating costs for algae culture by saving on labor and water treatment

We’d Love to Hear From You

-

Address

3374 Burns Avenue, Victoria BC, Canada, V8Z 3P2

-

Hours

Monday - Friday, 09:00 - 17:00

-

Email

-

Phone

-

Toll Free