February 19 2021

Derisking Scale-Up

How to de-risk the scale-up process?

We’ve all been there as a researcher or biotech professional. The strain of algae culture or microbes we are growing in our lab is thriving. It seems so straightforward and simple to culture, we believe we have it figured out. We easily create replicates in the lab at bench scale. We are now ready for the true test: scale-up time! Will this results we have come to expect in the laboratory carry over to a commercial or industrial scale? What is one of the major steps we can take to increase success?

Maintain Culture Parameters

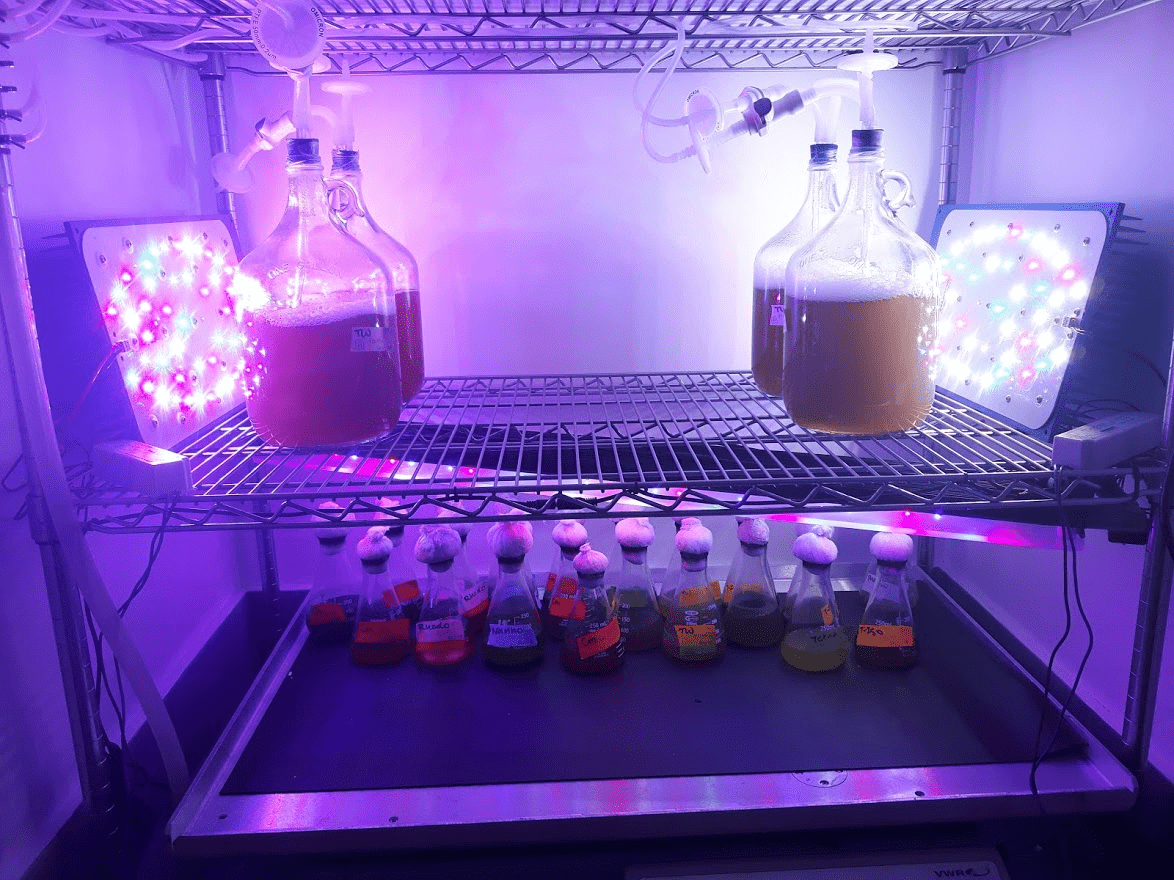

Knowing exactly what parameters are required for the perfect culture is the first step to set yourself up for success. Understanding your temperature, nutrient, light, and pH requirements is critical for any size culture. How do you plan to get from your 5-20 L perfectly controlled lab culture to a large open raceway pond or 10,000 L tubular system and beyond? In most cases, inoculating directly from your 5-20 L vessel probably is not the answer.

Seed Train

That’s where a medium volume PBR for seed train production (pre production scale-up) can be the solution to bridge that gap. If you believe that being able to maintain control of your culture as your scale is important to you, it may be time to look at an Industrial Plankton Bioreactor as an option.

Batch or Continuous Culture

Does your culture require batch, continuous, or semi-continuous harvest rates? Once you have inoculated your Industrial Plankton Bioreactor you can choose which harvest rate works best for your specific situation. Run the automated CIP system in between culture runs to prepare the vessel for your next culture scale-up.

Scale-Up Basics

If you’re looking at how to scale-up your flask to carboy culture with minimal equipment, please check out our “Sterile Algae Transfer With Minimal Equipment” video.