February 28 2020

Why use Bioreactors for Live Feeds?

Automated Bioreactors For Live Feeds

Live Feeds is a bottleneck. Reliably producing enough live feed is the bottleneck for many shellfish, shrimp, and marine finfish hatcheries. The feed has to be good quality, with both high nutrition levels and low pathogens levels.

Without enough feed, animals starve or are underfed. Operating a hatchery, you’ve probably calculated the cost of this loss, and weighed it against the live feed’s production cost.

The true cost of poor quality live feeds is often given less attention, since it’s usually impossible to calculate the impact on the entire value chain. Live feeds are commonly contaminated with pathogens that increase mortality of hatchery animals, or even kill the entire cohort. Animals that do survive by fighting off early infections often have less efficient feed conversion ratios and lower growth rates. This results in lower yield in the grow-out phase.

To help solve these problems with reliable production and feed quality, Industrial Plankton has developed live feed equipment for producing algae and zooplankton, with a focus on maintaining a stable biosecure culture environment.

Algae

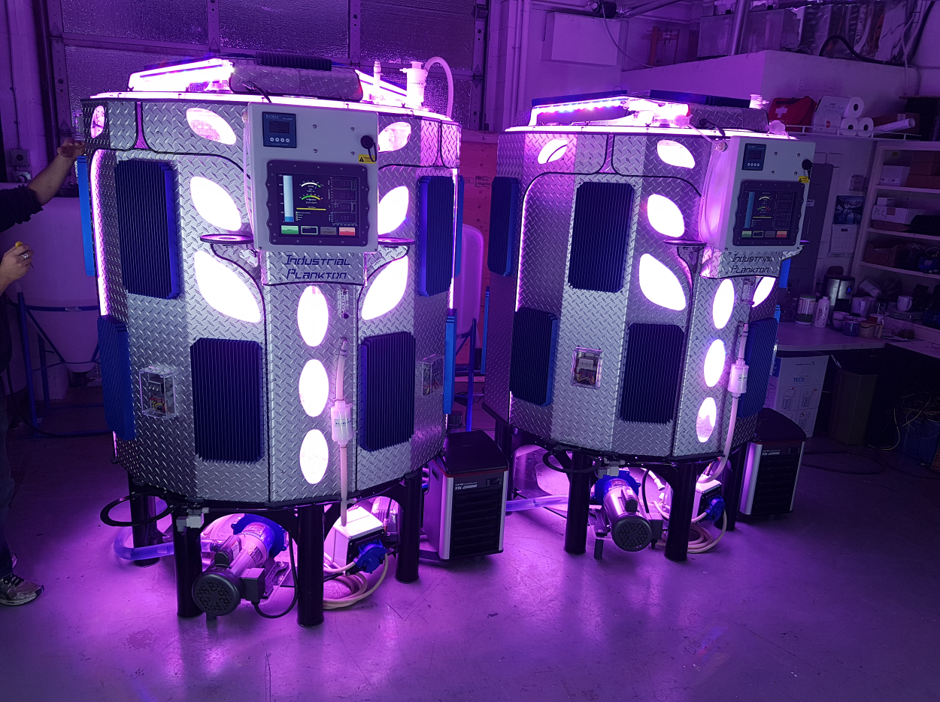

Consistently producing algae on site can be time consuming and unreliable. By maintaining a clean, stable culture environment and automating many routine functions, Industrial Plankton photobioreactors (Fig 1) make it easy to consistently produce algae to meet hatchery needs.

Biosecurity

A big challenge to producing clean algae outside a lab is biosecurity. A single grazer or pathogenic bacteria can invade a culture and establish a population, causing reduced productivity or larval mortality. To establish a clean culture environment, the PBR 1250L uses an automated clean-in-place (CIP) system to clean and disinfect the tank before starting a new culture. Additionally, the bioreactor has micron filters to maintain biosecurity while adding the water, nutrients, air, and CO2.

To start a new culture, the inoculum is connected to the PBR with sterile disconnects, then pumped in with a biosecure pump. By maintaining biosecurity a PBR can continuously produce high quality clean algae for months.

Reliability Through Automation

After inoculation, the next step is providing the right temperature and the amount of nutrients, CO2, and light needed to sustain production and prevent culture crashes. To minimize time and effort, the PBR 1250L automates these functions. Nutrients are stirred and added automatically, and closed loop pH control adds CO2 as the algae grows, maintaining constant pH and preventing carbon limitation. Harvesting can be done with the push of a button, scheduled to harvest automatically, or set to harvest continuously. Temperature is controlled using a chiller and an internal heat exchanger. As long as the PBR has a supply of water, CO2, and nutrients, it can produce algae automatically.

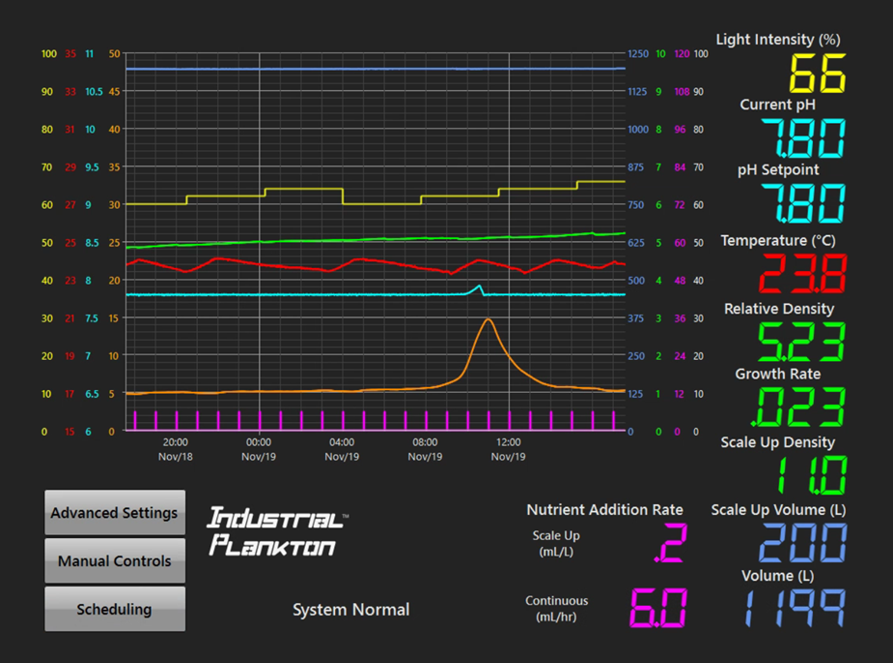

A touchscreen control makes it easy to adjust settings. The controls also log and graph the sensor data, simplifying troubleshooting (Fig 2).

Cleaning

One of the most unreliable and labour intensive tasks required for culturing algae is cleaning tanks. Therefore, by providing a self-cleaning biosecure tank, algae cultures can grow productively for longer. When a tank needs to be cleaned, the PBR 1250L’s automatic cleaning system removes the need for manual cleaning. This works like a dishwasher to pressure wash the inside of the tank.

Cell Density

When culturing algae, it’s important to quantify algae biomass. However, counting algae cells on a microscope is time consuming and requires technical skills. To reduce the need for manual cell counts, the PBR 1250L uses a density sensor to output a linearized 0-10 value (Fig 2 green). This realtime density feedback helps operators maximize productivity by seeing the effect of changing light, nutrient additions, harvest rate, etc.

Rotifers

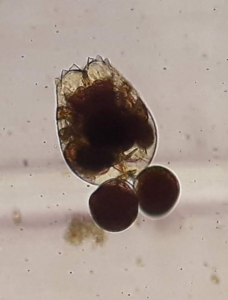

Rotifers are a critical first food for many larval fish, but are labour intensive to produce, and are a common source of vibrio and other pathogens.

Most rotifer production is still done in batch. Consequently, the problem with batch production is lack of control over the bacterial population. Vibro is often present in rotifer cultures, or introduced with incoming water, so operators are often scaling up a batch of vibrio along with the batch of rotifers.

In a stable environment without excess organic waste, pathogenic bacteria can be kept in check. If system parameters are unstable, the fluctuating organic load can allow faster growing pathogenic bacteria to rapidly increase in numbers. In a stable system, the bacterial population becomes dominated by beneficial heterotrophic bacteria.

The constant removal of organic waste from the culture is also critical. This is because high levels of organic waste generally encourages growth of opportunistic bacteria.

Reliability Through Automation

To reduce levels of pathogens in the culture, the Industrial Plankton Rotifer System (Fig 4) operates as a continuously recirculating system with an attached biofilter. This provides a stable culture environment rich in beneficial bacteria, preventing opportunistic pathogenic bacteria from proliferating.

The rotifer system uses a touchscreen interface to display and log data, and controls vital parameters such as temperature, pH, and dissolved oxygen. Additionally, to maintain good water quality, organic waste is removed using a self-cleaning mechanical filter, a foam fractionator, and finally a biofilter to detoxify ammonia.

Conclusion

Live feeds produced from Industrial Plankton’s automated equipment are a perfect solution to the bottleneck experienced by many shellfish, shrimp, and marine finfish hatcheries. The reliable production of high quality live feed in a stable biosecure culture environment allows for improved nutrition and lower chances of early infections in animals. Subsequently, this transitions into higher hatchery survival and growth rates. The equipment is currently operating in 18 countries to support the hatchery production of oysters, mussels, clams, vannamei shrimp, monodon shrimp, and marine finfish.

This article can be found in Hatchery Feed & Management Magazine – Volume 8, Issue 1, 20202