January 31 2017

Algae vs Disease

COULD ALGAE BE USED TO CURE DISEASE? THE ANSWER COULD BE RIGHT HERE IN WILMINGTON

In case you missed this article from Port City Daily in Wilmington, North Carolina

By Benjamin Schachtman

WILMINGTON – There is a quarter of a billion dollars on the table, and the University of North Carolina at Wilmington has one of the best seats.

UNCW and the Marine Biology in North Carolina Center (MARBIONC) were recently named as part of the $250 million National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMB) initiative. Financed in part by the Department of Commerce, the initiative is aimed at developing biopharmaceutical manufacturing in the United States.

The private-public initiative brings together a consortium of industry leaders, universities and government partners to develop both pharmaceutical products from living cells and the techniques used to manufacture them.

Port City Daily spoke with Dr. Daniel Baden, executive principal of MARBIONC, to learn what the center does and what the initiative means for the area.

”It’s about the chasm of death,” Baden said. ”The philosophy of MARBIONC is building bridges between the university and industry. So many biotechnology discoveries don’t make it across the chasm of death, they go all the way through the research process and just fall to their death and disappear before they become applied technology. So the university, research, it’s got to get a little closer to industry, or industry has to get a little closer to the academy. ”

This affinity for what Baden calls ”translational science,” bringing academic research together with industry production, is the reason MARBIONC was accepted into NIIMB’s top tier of facilities.

”Obviously, we fought hard to be near the top of tier one. Not just for the funding opportunities but for the administration,” he said. ”We wanted a seat at the table, to help steer where this thing goes over the coming years.”

Baden said, ”It’s a win-win for education and business. There’s about 10 to 20 projects announced, twice a year, for six years. The National Institute for Standards and Technology funds about $70,000,000 and industry is providing the rest. These are essentially problems in the field, and the consortium brings together the research universities and businesses to solve them.”

The initiative members both compete for projects and cooperate to complete them. There are multiple benefits for the University.

”First, of course, is that students at UNCW get real world experience. Their endgame is usually writing a paper or a presentation, here their endgame is working on a real-world project. Second, we build relationships with industry, so that – when we want to fund a pure research project, or have a post-doc position – we have a seat at that table already. Also, we have industry investing in equipment that we’re then continuing to use.”

Baden said its good for business also.

”For businesses, including local businesses, we can solve research problems for them,” he said. ”We work with Alcami, for example. We can basically deliver systems for manufacturing pharmaceuticals, in our case derived from marine life. And we work with equipment manufacturers, like IKA here in Wilmington. We’re helping to design and test equipment for them. And, of course, in the process we are in effect training their next generation of workforce.”

Asked if there were any concerns in bringing businesses into the academic world, Baden said ”Yes, absolutely.”

”And that’s why we have this building. We used to share space with the Center for Marine Science, since we began in 2005. But we wanted, both physically and philosophically, to separate what we do from the university,” he said. ”They’re pure research over there, there’s no teaching activity over here. You can walk across the courtyard between the two, we share core resources, but there’s a real separation to mitigate the impact of industry on academics.”

The $30,000,000 MARBIONC building, 69,000 sq. ft. of laboratory and meeting space, opened in 2013. Funded in part by the National Institute for Standards and Technology, Baden says the building grew out of the vision of the American Recovery and Reinvestment Act of 2009.

”The Obama administration, at least for the next week or so, they are focused on high-value, low foot-print manufacturing jobs,” Baden said. ”And the General Assembly [of North Carolina] has told us, economic development is part of our mandate.”

MARBIONC’s role in the development of Brevenal, a leading drug treatment for cystic fibrosis and COPD, is one example, according to Baden.

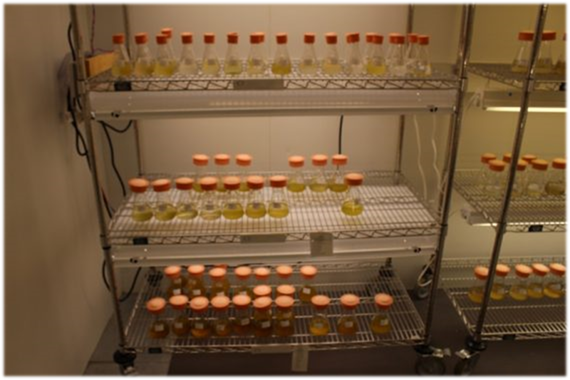

The discovery grew out of the MARBIONC’s experiments in culturing and scaling up colonies of algae. Baden and his team started out with a single culture of algae.

”It dates back to 1958, Bill Wilson from Texas,” he said. ”It was at the Florida Department of Natural Resources in St. Petersburg. I went a got a sample in in 1973. Well, the first one I put in an icebox, and that didn’t work out too well. So I had to go back and get a second sample. But that’s the one, we’ve cloned it many, many times.”

From that single culture, Baden and his team have created distinct and proprietary strains, as well as collecting hundreds of other species of algae. Baden said he asks anyone who works at the UNCW CMS or MARBIONC to keep algae in mind when they travel.

”I tell them, if they’re near any major body of water, on their last day of vacation, take a water bottle, empty it, and scoop up some water and sediment,” he said.

This is just one part of how Baden and his team have assembled at least 750 different strains of algae. MARBIONC researches have only started analyzing them. Many algae have toxic properties – responsible for the toxicity of ‘red tides,’ the algal blooms that can kill fish and marine mammals. But one particular species contained a chemical with quite the opposite reaction.

”So, we cultured this algae from a red tide in Florida and we were isolating the toxins,” he said. ”These are neurotoxins, and they caused a lot of coughing and sneezing, mucus reactions. One of them seemed to act not like a toxin, but like an antidote. We moved on to animal tests, administering alongside toxins and it reduced the reaction. Then we administered it preemptively, as prevention.”

Baden recalls hearing from a lab tech, ”I think you’ve got a cure for cystic fibrosis here.”

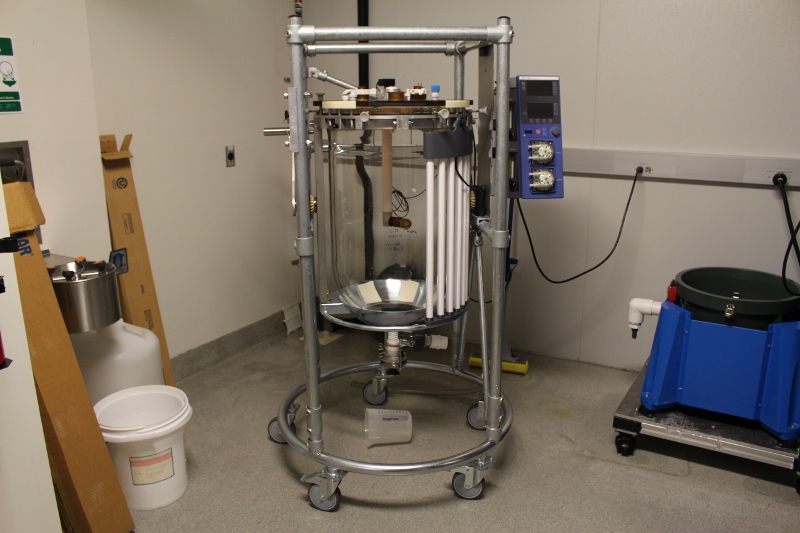

”That’s a huge industry, right there, but it doesn’t require the massive manufacturing spaces of traditional industry,” he said. ”We could manufacture the materials to supply the entire United States population of cystic fibrosis with medication in an 800 square foot lab.”

Baden, gesturing to the row and row of Erlenmeyer flasks, added, “You have to keep it mind, we’ve only really looked closely at 30 of these. We’ve just scratched the surface.”