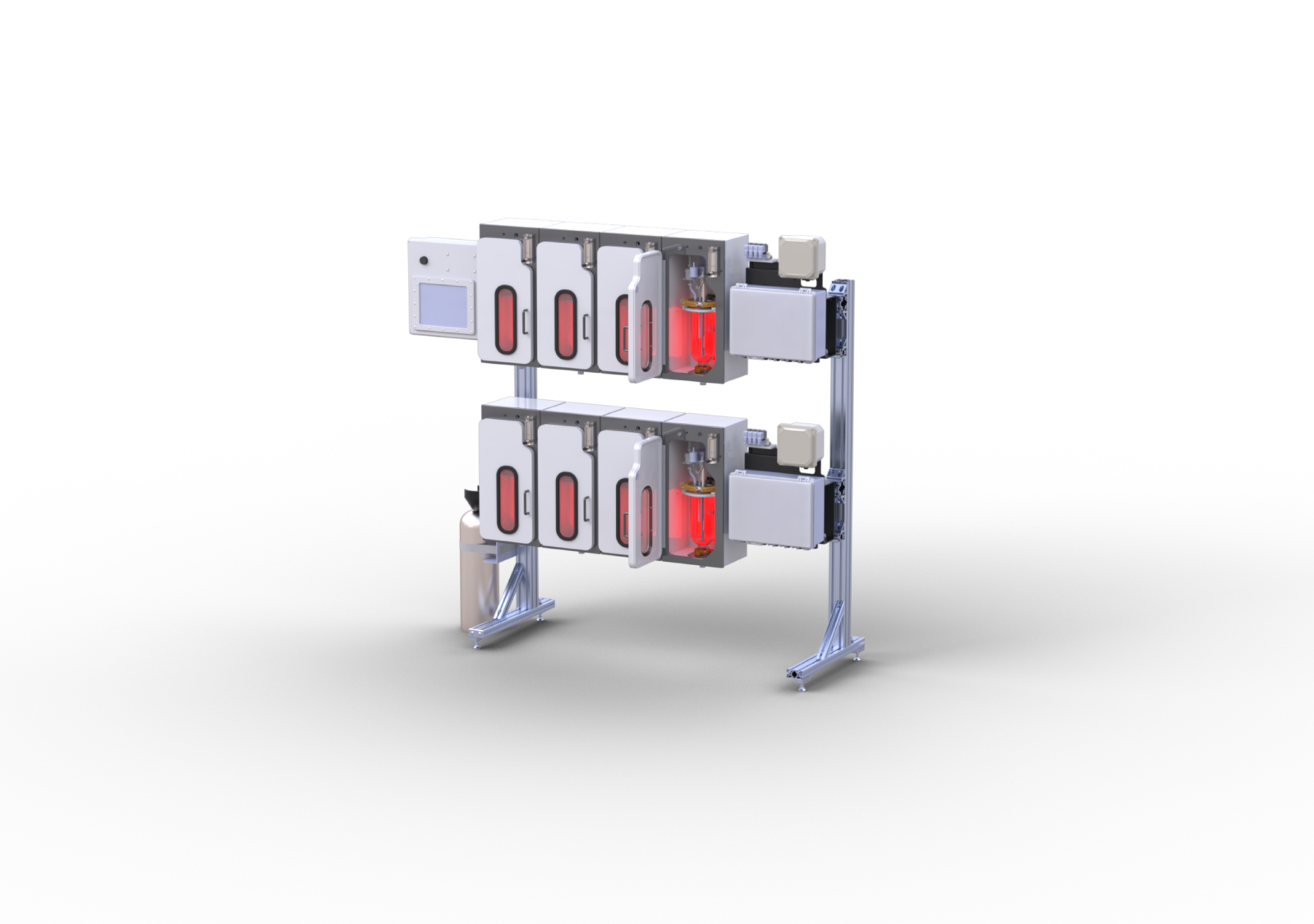

The PBR 2500L Dual Algae Bioreactor is designed to reliably grow two algae cultures in separate 1250 L tanks.

Ideal for aquaculture hatcheries producing shellfish, shrimp, etc., or for greenwater and zooplankton feed production in marine finfish hatcheries.

Also ideal for biotech seed chain or pilot scale production.

One PBR 2500L replaces up to 70,000 L of traditional batch tanks or 60 continuous 400 L bags.

Culturing biosecure algae is easy with the closed photobioreactor and clean-in-place (CIP) system, while automation and easily adjustable parameters make cultures more productive and reliable.

The 1250L Algae Bioreactor is designed to reliably grow algae in an industrial setting.

Ideal for aquaculture hatcheries producing oyster, mussels, geoduck, clam, scallop, shrimp, etc., or for greenwater and zooplankton feed production in marine finfish hatcheries.

Also ideal for biotech seed chain or pilot scale production.

One PBR 1250L replaces up to 35,000 L of traditional batch tanks or 30 continuous 400 L bags.

Biosecure algae is easy to culture with the closed photobioreactor and clean-in-place (CIP) system, while automation and easily adjustable parameters make cultures more productive and reliable.

The PBR 100L Research Algae Bioreactor is designed for researchers who need a meaningful volume of algae to feed aquaculture animals such as shellfish or shrimp, and for greenwater or zooplankton feed production.

The lab scale photobioreactor is also ideal for biotech researchers testing algae for applications in biofuels, and production of omega-3’s, carotenoids, etc. Biosecure algae is easy to culture with the closed tank design and clean-in-place (CIP) system.

Automation, a sealed environment, data logging, real-time graphing, and easily adjustable parameters make this reactor ideal for research applications.